Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

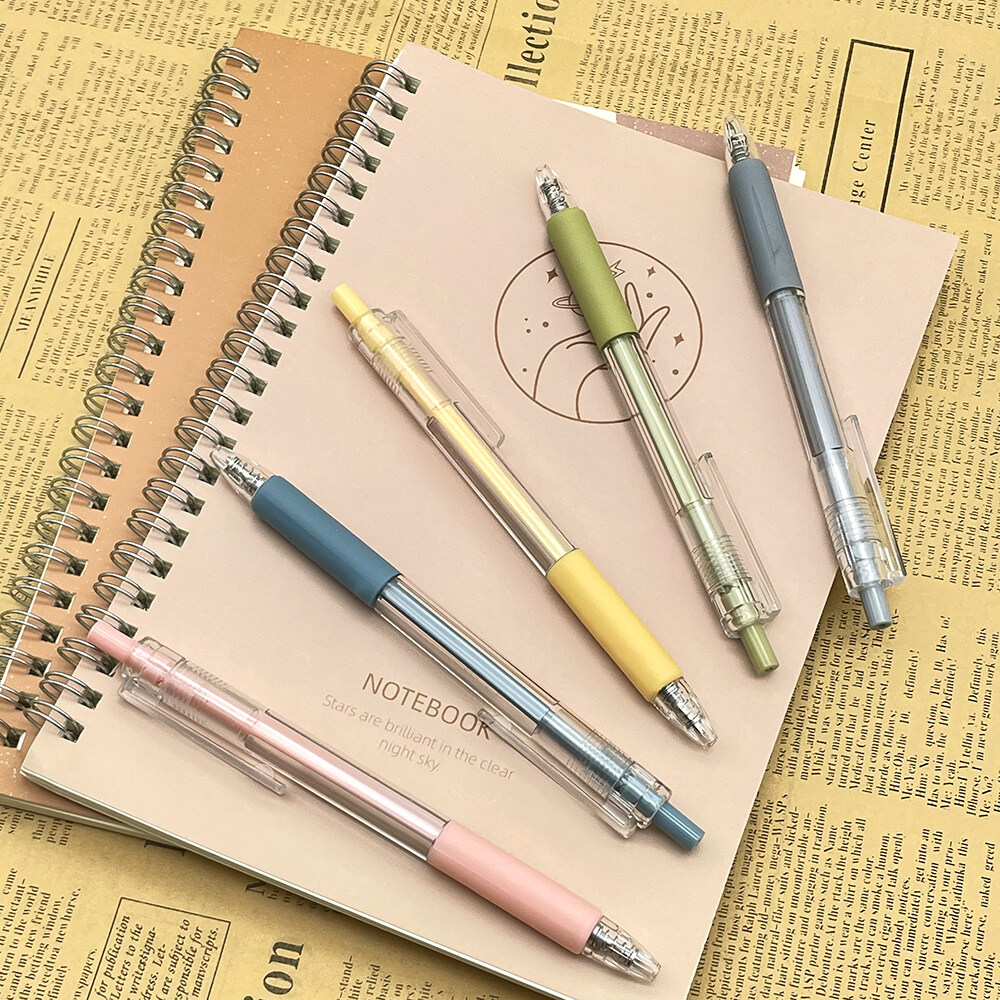

Many people do not know that the technology used in ordinary stationery, such as ballpoint pens, is not ordinary. Do you know your ballpoint pen?

A ballpoint Pen is a pen that brings out the writing medium by rolling the ball at the front of the pen or refilling.

A ballpoint pen is a pen that uses tiny rotating balls made of brass, steel, or tungsten carbide to release ink onto paper while writing.

The ballpoint pen is quite different from its predecessors - reed pens, feather pens, metal-tipped pens, and fountain pens.

The reason why the ballpoint pen can ink smoothly is that during the writing process, the small ball of the ballpoint pen head rolls under the friction force generated when it contacts with the paper, to bring out the ink in the pen core and form handwriting.

In short, the structure of the ball point pen head is to embed a ball bead at the top of the ball base body, so that the ball bead can rotate smoothly and not easy to fall off from the ball base body.

There are mainly three technical difficulties in the manufacture of ballpoint pen heads. First of all, to ensure a smooth writing experience, cooperation between the ball bead and the ball seat is crucial. The gap between the ball bead and the ball socket is about 5 microns. If the gap is too small, the ink cannot flow smoothly; If the gap is too large, it will cause ink leakage, or even make the ball drop from the pen tip.

Secondly, in the process of writing, due to the constant friction between the pen tip ball and the paper, the gap between the ball and the ball seat will gradually become larger. Over time, ink is easy to leak out of the gap, affecting writing.

In addition, the ballpoint pen tip has extremely high processing precision and assembly precision. There are uneven steps and oil guide grooves for guiding ink in the pen tip. The machining accuracy of each oil guide groove is required to be 1 μ m.

All these factors put forward higher requirements for the material performance of ballpoint pen balls.

There are more than 20 processes for making a ballpoint pen head. The materials required for each process are very fine and complex, and these materials require high precision. For example, the overall thickness of the pen tip is less than 0.1mm, but the error should not exceed 0.003mm! The construction difficulty is equivalent to that of an aircraft carrier.